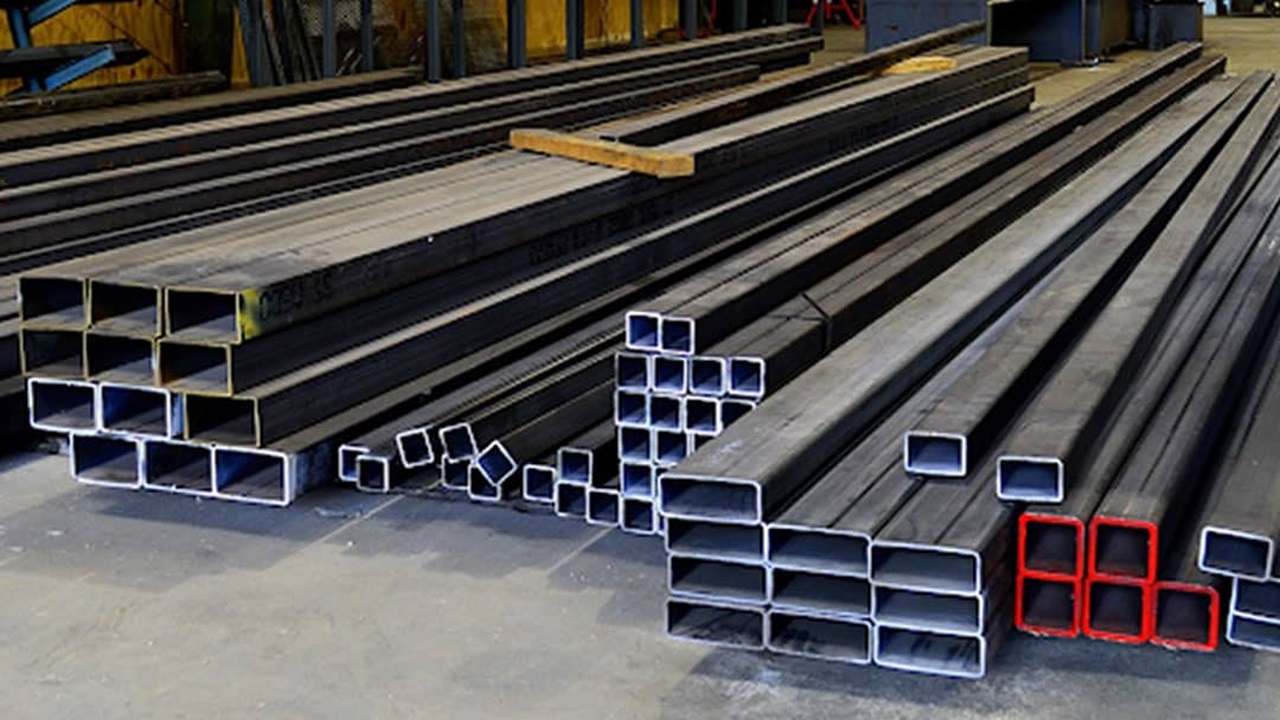

Square tubes are widely used in various structural and industrial uses as frameworks for construction and manufacturing machinery. They are strong, durable, and can easily be adapted to suit several applications. The size of the square tubes is one of the most important aspects that determine the performance of the material since all the dimensions affect the strength and usability of the material. Knowledge of the correlation between the Square Tube Size and its strength will assist the decision-makers in making the right decisions on the right square tubes to use.

The Basics of Square Tube Strength

The strength of a square tube is found in some respects, which include the material of the tube, the wall thickness, and the size. Each of these plays a role in how much weight it can carry across the tube, how stiff or strong the tube must be, and the efficiency with which it can work when there is tension or similar situations. Most of the square tubes are made from steel, aluminum, or stainless steel simply due to strength and resistance. This shows that other important factors that define the strength of the tubes include the thickness of the walls. Thicker walls imply more material and as a rule, more material implies a greater load-bearing capability. But it is not only the thickness that is an issue, size and dimensions are very important as well.

How Tube Size Impacts Strength

The size of a square tube is usually represented by two main measurements: the outside dimensions and the wall thickness. These numbers in combination determine the load-carrying capacity of the tube, the stress, and the pressure it can withstand.

Outside Dimensions

The measurements of outside Dimensions are between one edge of the tube to the other edge of the tube. The various sizes of square tubes include thin ones for furniture and thick ones for construction. As the outside dimensions rise, the tube is usually made stronger and less easily bent. Cutting large square tubes also enables the design of structural mechanisms to support higher weight proportions at increased stability.

Wall Thickness

The thickness of the wall gives a measure of strength as well as the sturdiness of a square tube. The higher the thickness, the greater the resistance to compressive as well as tensile loads due to a tube’s walls being thicker. The higher load bearing of a tube by having more wall thickness increases so the stainless steel tube is suited for stressing constructional elements such as the support structure for buildings or an industrial framework. Thin-walled tubes weigh less and are more versatile in handling once formed. They are good only for low-stress applications.

Typical Square Tube Sizes and Their Uses

Depending on the various strengths required, different sizes of square tubes have been used. Below is a look at common square tube sizes and their typical uses:

1 inch by 1 inch (25.4 mm by 25.4 mm)

Square tubes of a smaller size such as 1 x 1 inch are relatively light and easy to maneuver. They are utilized in furniture, light shelving, and other minor framework applications. They are best suited for low-load applications because of their compactness.

2 x 2 inches (50.8 mm x 50.8 mm)

These medium square tubes are ideal for both commercial and residential buildings. They are good in stiffness along with thickness, and it is widely used in the construction of light frame structures and general-purpose support.

4 x 4 inches (101.6 mm x 101.6 mm)

Larger in size, 4 x 4-inch square tubes offer better load-carrying capability than the usual sizes. These tubes are used in the most demanding applications such as in structures, buildings, and large machinery support frames. This is because they are big structures and can, therefore, endure more load and pressure as is the case with industries.

6 x 6 inches (152.4 mm x 152.4 mm) and above

The largest of the square tubes are extra-large and are the most rigid and can support heavy loads. They are employed mostly in special conditions, for example working over bridges, equipment used in construction such as cranes, and immense industrial buildings. These tubes provide maximum strength and rigidity and are suitable for use where extra heavy duty is required and will not bend or buckle.

Conclusion

When choosing square tubes for any project, size is one of the most important determinants of the strength of the tubes can only be achieved when one knows how the outside dimensions, wall thickness, and application are connected. Thin-walled square tubes with small to medium cross-sectional dimensions are suitable for low-stress use while thick-walled large square tubes are suitable for high-stress applications. Tus Pipe has a range of square tube sizes to address these requirements and provide products that are reliable, effective, and strong across a range of applications.